- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

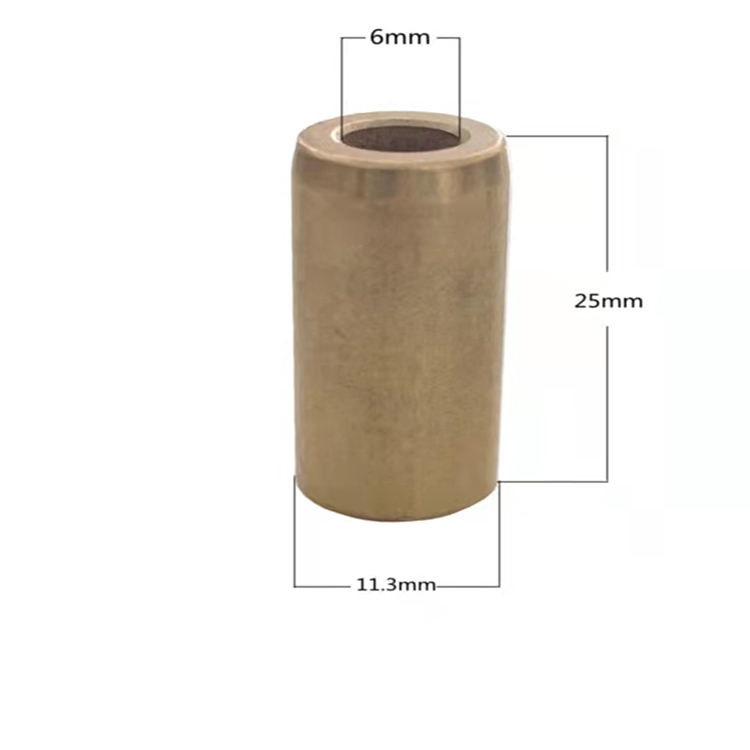

Brass bushing CNC turning parts

Send Inquiry

Brass bushing CNC turning parts are brass bushings machined using CNC lathes, usually with high precision and smooth surface quality. CNC lathe is a CNC machine tool, which can control the movement and machining process of the machine tool through a computer program to achieve high-precision and high-efficiency machining.

The manufacturing process for brass bushing CNC pin parts consists of the following steps:

Material preparation: Select the brass material that meets the requirements, and carry out the necessary treatment, such as cutting, grinding, etc.

CNC lathe machining: The brass material is placed on the CNC lathe, and the movement and machining process of the lathe are controlled by a computer program to achieve accurate machining.

Surface treatment: Necessary surface treatment of the processed brass bushing, such as polishing, chrome plating, etc., to improve its surface quality and corrosion resistance.

Inspection: The finished brass bushing is inspected to ensure that its dimensional accuracy, shape accuracy and surface quality meet the requirements.

Brass bushing CNC pin parts features include:

High precision: CNC lathe processing accuracy is high, can ensure the brass bushing dimensional accuracy and shape accuracy.

Smooth surface: Through the surface treatment process, smooth surface quality can be obtained, improving its wear resistance and corrosion resistance.

Suitable for high load applications: Brass material has high strength and wear resistance, suitable for high load application scenarios.

Long life: Brass bushing CNC pin parts have a long service life due to their high precision and smooth surface.

In short, brass bushing CNC pin parts are a high-quality mechanical part suitable for a variety of high-precision, high-load application scenarios.